Big blend

Characteristics

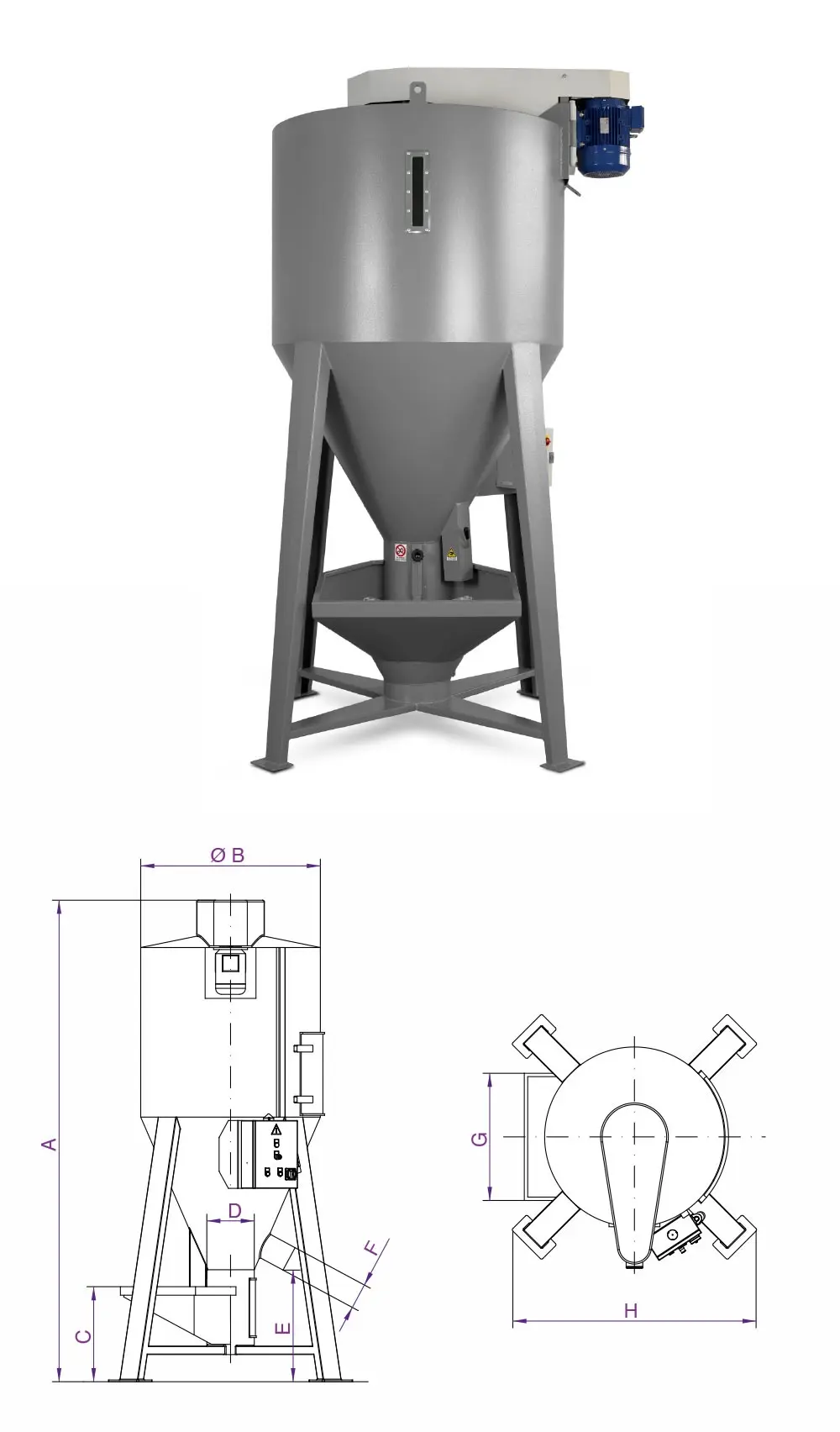

● BIG BLEND mixer is a solution that has always been used for mixing plastic material granules. It consists of an outer frame made of painted sheet metal and an internal screw (optional in BIG BLEND 2/3 and 4) inside a tube for mixing the contents. The material to be mixed is fed into the loading hopper, the screw receives it from below and carries it upwards releasing it on top, spreading it inside the mixer body with a radius of 360°. After about 15/20 minutes, the material is perfectly mixed

● The BIG BLEND includes the control panel, with the Start and Stop functions and time settings

● The inspection hatches for the screw conveyor and mixer are protected by safety microswitches

● The BIG BLEND includes the control panel, with the Start and Stop functions and time settings

● The inspection hatches for the screw conveyor and mixer are protected by safety microswitches

Technical features

● The mixed material outlet tube is complete with gate valve

● Screw is enclosed in a tube along its entire length

● When the inspection hatch is open, big blend will not run

● Both doors have a pair of safety latches and microswitches for protection

● The power cable and cables of the micro switches are protected in a cable duct

| King Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dimension | Capacity | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) |

| BIG BLEND 2/3 | 500 lt | 2550 | 850 | 600 | 200 | 800 | 150 | 850 | 1150 |

| BIG BLEND 4 | 1000 lt | 3050 | 1060 | 650 | 280 | 800 | 200 | 750 | 1250 |

| BIG BLEND 5 | 1800 lt | 3200 | 1400 | 700 | 320 | 800 | 230 | 950 | 1400 |

| BIG BLEND 6 | 2500 lt | 3500 | 1500 | 700 | 320 | 800 | 230 | 950 | 1450 |

| BIG BLEND 7 | 3500 lt | 3900 | 1600 | 700 | 320 | 800 | 230 | 950 | 1500 |

| BIG BLEND 8 | 5000 lt | 4200 | 1900 | 750 | 320 | 800 | 230 | 1000 | 1800 |

| BIG BLEND 9 | 8000 lt | 4600 | 2350 | 750 | 320 | 800 | 230 | 1000 | 1950 |

| BIG BLEND 10 | 10000 lt | 5100 | 2350 | 750 | 320 | 800 | 230 | 1000 | 1950 |

| BIG BLEND 11 | 14000 lt | 5600 | 2450 | 750 | 320 | 800 | 230 | 1100 | 2150 |

Send us a message!

Contact form

Have any questions or concerns?

Let us know and we will be happy to advise you!