HYDROBRG & SIREG

Chilled Water System

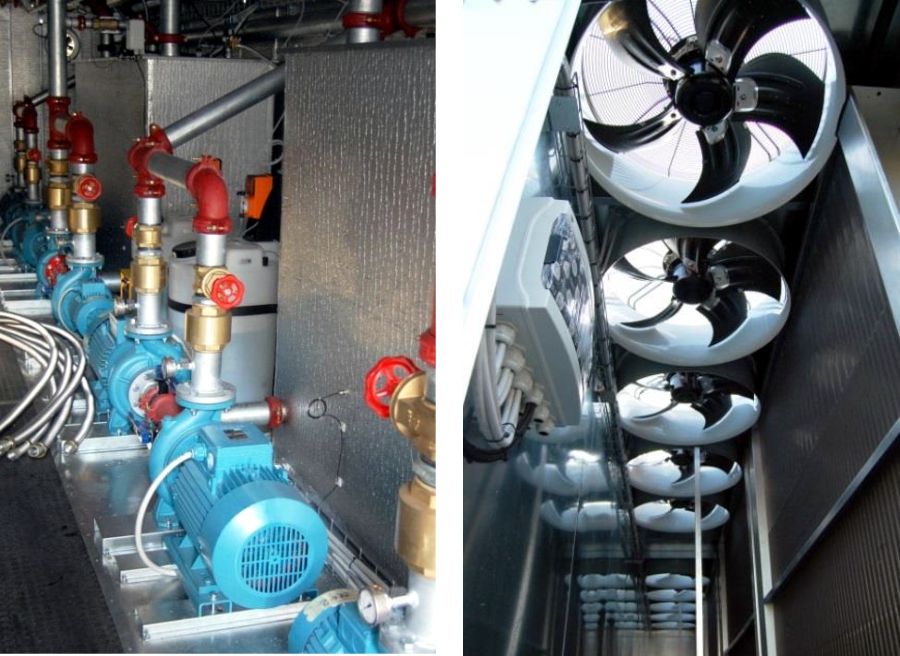

Modernization of the chilled water system involving the replacement of the old cooling system with a new energy-efficient system using IF units and changes in the piping inside the production hall.

The project required a high cooling capacity due to the efficiency of the contractor’s machines. In the project implementation, we used the most environmentally friendly and advanced solutions to take care of the environment and reduce the demand for electrical energy. The system is based on two independently operating refrigeration units, which are protected against water freezing during downtime in the winter.

The following units were used in the project:

- HYDROBRG – An adiabatic fan battery with sprinkler system was used to cool the oil in the machines. The unit, thanks to its automatic sprinkling and additional water distribution plates, performs excellently in hot weather. Another advantage of this unit is its reliability and compatibility. The battery, together with the tank-pump unit, is designed to operate 100% on water despite the location of the entire unit being enclosed

- SIREG – it is a combination of a chiller and a fan battery with a water condenser. The device has been adapted for cooling forms and thermostatic machines. A great advantage of SIREG is the free-cooling function, which allows the production of cold water at low operating costs, given our climate. Additionally, the device is self-sufficient and easy to use.

The end result is a system that gives the customer flexibility in terms of both relocation and capacity expansion.

Check out what we have created!

Photos from the project implementation.

Check below what we have achieved together in cooperation with our client.